Walk up and down the aisles of any grocery store and you’re sure to see at least one, but more likely dozens, of Ocean Spray products. The cooperative nearly synonymous with “cranberries” makes products on a large scale, with a vast network of growers and facilities to get these products on grocers’ shelves.

In 2011, the Ocean Spray plant in Kenosha, WI (one of nine plants)—the plant responsible for juice production, packaging, and more than 80 percent of all of the country’s cranberry sauce production—was facing widespread problems. The plant struggled with safety, performance, and employee satisfaction. Things had to change in order for Kenosha to deliver on its commitments—and change it did. Ocean Spray turned to Partners In Leadership for Accountability Training and culture change services to help save the plant and put it on the path to success.

“Broken Down Kenosha”

The step-change in plant behavior began one August morning in 2011. An ominous mood had settled over all those gathered at the Kenosha plant warehouse, where they knew the new plant manager, Tim Peoples (now Plant Director, Food Manufacturing Network Lead), was going to be introduced. When he accepted the position, Tim knew things had gotten progressively worse at the plant, but he was shocked to learn that morning how bad things really were—and that he had only 18 months to turn things around and fix the five areas where they were failing:

- Poor safety performance

- Highest cost producer in the Beverage Network

- Poor material loss results

- Poor employee morale and engagement

- Concerns over introducing a multi-million dollar capital investment in the plant

This was not going to be an easy task for Tim.

Fast-forward two months later to a senior management meeting at corporate headquarters. During the meeting, the direness of the situation was hammered home when VP of Manufacturing Erich Fritz (now VP of Research & Development and Engineering) showed Tim and the other senior managers a picture of how the Kenosha plant was viewed by Ocean Spray’s senior leadership:

Erich said to Tim, “Just so you don’t forget, this is the current state of your facility.”

The image was shocking to Tim. He got the point—the plant was declared a breakdown.

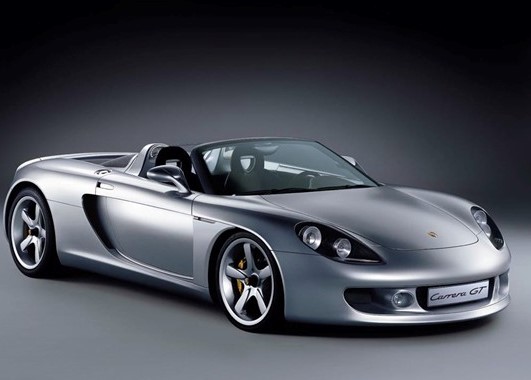

After the meeting, Tim asked Erich for the picture, telling him, “I got it, I own it.” In those words, Tim was telling his boss, “I See It—I grasp the reality we’re facing—and I Own It—I’m taking accountability for the problem.” But Tim knew it wasn’t enough for him to be the only one to see and own the problem. If they were going to solve the problems at the plant and turn things around, everyone at the plant would need to take accountability for the situation. So once he got the picture, he showed it to plant employees at his meetings with them, explaining, “We need to own this. The only way we’re going to change this image is to own it.” They, too, were upset that corporate viewed them this way. Yet, Tim didn’t want them stuck with this image of themselves; he knew they needed another image—one that was positive, powerful, and inspirational—so he showed them a Porsche Carrera GT convertible telling them “This is who we’re going to become!”

After the meetings, Tim had the picture of the Volkswagen blown up into a 4’ x 5’ picture and hung in the employee cafeteria, entitling it “Broken Down Kenosha.” He also blew up the picture of the Porsche and cut it into 24 puzzle pieces—each piece they would earn to cover up the broken down VW. Each of the puzzle pieces represented a challenge they needed to overcome or an obstacle they needed to solve. This would be a daily, visual reminder to all the employees at the plant about their progress in turning around the plant.

This, however, wasn’t all that needed to be done. As Tim explains it:

I knew we had to do things differently…We had to move from an Us vs. Them mentality to a working together mentality. We could no longer be stuck in our individual silos, we had to collaborate with one another. We had to be willing to reach across functional boundaries, we had to be willing to embrace labor and management coming together…We had to evaluate and change our spending habits; in other words, we had to develop a mindset of being fiscally responsible. Lastly, we had to shift our focus from ourselves to a focus on those around us… we had to deliver impeccable customer service to our fellow coworkers.

The Transformation Begins

Tim had a good idea of where to go for help. He had read both The Oz Principle and Change the Culture, Change the Game authored by Roger Connors and Tom Smith and was impressed. He decided that the next step would be for his leadership team to read Change the Culture, Change the Game and spend the time discussing how the content applied to their situation. One of his leadership team suggested that Tim call the authors and their company, Partners In Leadership (PIL). Tim went to the HR manager and discussed the value he saw in working with PIL. The company management liked the idea and gave Tim the green light. So Tim called PIL and spoke with Tom Smith, one of the authors and cofounders/co-CEO of the company, and Tanner Corbridge, Business Unit President.

After discussing the situation with Tim, Tanner was able to identify a culture change solution that would turn things around at Kenosha. He explained how getting the workforce aligned around the key results would benefit the organization by creating lasting change. The proposal by PIL was a significant investment, and Tim was amazed at the senior leadership’s commitment to turning things around at Kenosha. With the approval given, Tanner and a regional VP from PIL began working with Kenosha.

Signs of Change

One of the first things that needed to be addressed was getting Kenosha’s management aligned around the plant’s key results and what type of cultural transformation was needed in order to achieve those goals. In a two-day PIL-facilitated workshop, the plant’s leadership teams defined four key results that everyone at the plant would be accountable to achieve and developed the plant’s cultural beliefs. PIL described cultural beliefs as core beliefs that demonstrate how people in the company need to think and act in order to create and sustain a culture that is accountable to achieve desired results. “We deconstructed the culture and then reconstructed it around six cultural beliefs…The cultural beliefs are our guiding principles on how we behave and how we expect others to behave,” recalls Tim.

PIL trained everyone in the plant, and management and operations together presented the new key results and the cultural beliefs to the plant workers, emphasizing to the workforce that delivering on key results would be a direct output of how well they lived their cultural beliefs. And to further reinforce the new culture of collaboration and team mindset throughout the plant, the leadership team began spending time on the shop floor. While at first this shocked the plant employees and made them anxious, they came to expect management to be there engaging them in conversation, addressing obstacles, helping them solve problems, and being supportive of their needs. Moreover, management, taking to heart the critical importance of feedback, engaged in 360-degree feedback exchanges. The management team set aside time to go offsite and review the feedback they had received and engage in a “candid, open, and honest two-way dialogue,” which Tim says “was very powerful and helped the management team grow and elevate.”

“New and Improved Kenosha”

Did everything flow smoothly without any setbacks? No. As Tim explains: “There were times at those early stages, despite my being gung-ho, that we wondered if we were making the progress we wanted or were seeing the results we wanted. PIL coached us through this and helped us believe we’d see the change in time.” And they did. In February 2015, Tim was thrilled to report that their efforts finally had paid off. Today, the picture of the old broken down Volkswagen now is completely covered by all 24 puzzle pieces of the Porsche, erasing from memory the idea that Kenosha was ever that rusty, beat-up VW bug. “Broken Down Kenosha” was no more. What made this accomplishment hit home was when VP of Manufacturing Erich Fritz sent a video message to the plant affirming that Kenosha was no longer broken.

Now Kenosha is perceived as the “New and Improved Kenosha”—a plant and a team that is top-of-the-line, powerful, and fully capable of continuing to deliver on the key results in the way they do now. Their current success blows away any concerns about them failing in the five areas that VP Erich Fritz identified at that meeting in 2011.

Poor safety performance:

- 506 days without a loss time injury

- 600,000 safe hours without a loss time injury

- 75 percent reduction in recordable injuries

- EHS (Environment, Health & Safety) Plant Of The Year

Highest cost producer in the Beverage Network

- Reduced cost per case

Poor material loss results

- On track to ring up a $750,000 credit in their material loss line item

Poor employee morale and engagement

- The Kenosha plant has been recognized as the best place to work in Kenosha County, which reflects the 60-plus employees nominating the plant as the best place to work.

Concerns over introducing a multi-million dollar capital investment in the plant

- Plant employees are exceeding production goals: When the line employees were told they needed to produce 30,000 cases on average a day, they went on to deliver close to 33,000 cases on average a day.

- No longer any concerns over a huge capital investment because of the improvements to performance and workplace culture.

Perhaps the most important result, though, is that the men and women who work there will remain employed and can continue to provide for their families—certainly, the immense value this provides to them and to their community is almost beyond measure.

These results reflect a remarkable turnaround of the plant and a real commitment to accountability. As Tim told all his management team regarding these results:

“This doesn’t happen without people living, breathing, and demonstrating the six cultural beliefs day in and day out. We could not have improved any of those results had we stayed in the place we were in nearly three years ago.

I want to emphasize this: If we get the accountability piece right, then we get everything right. In other words, our ability to continue to deliver on our key results depends on getting accountability right…the key to our ongoing success is going to be our ability to continue to embrace our cultural beliefs and our willingness to accept personal accountability in delivering on our key results.”

The Journey Continues

The employees at Kenosha have demonstrated that they aren’t that broken down Volkswagen anymore. In seeing and owning their problems, they were able to move ahead and solve them and do what they needed to do. Their commitment to personal and joint accountability has enabled them to change their culture and thereby turn the plant around so that they could deliver on their key results. And wanting to get even better at accountability, they’ve made the commitment to continue building their relationship with Partners In Leadership and get trained in additional Accountability Training programs.

Tim’s ability to recognize the power of culture and workforce alignment has ensured that the plant will continue its journey to produce amazing results, maintain high morale, and foster collaboration. And now Tim is headed down a different path. Impressed with Tim’s leadership and the results that Kenosha continues to produce, the Ocean Spray leadership team now has tasked him with management over a different plant. There, they hope to see Tim apply his knowledge of cultural transformation and lead the plant in developing a strong Culture of Accountability that will deliver desired results for years to come.

Although the roads traveled by Tim and the employees at Ocean Spray’s Kenosha plant may not have an end, they now understand how to navigate it for ongoing success: “Being in manufacturing, there’s no finish line. It is a journey with no set destination. We have mile markers along the way that we stop at and celebrate, but we continue on. It’s our culture that sustains that journey.” As Tim and his plant experienced firsthand, change the culture, and you change the game!

Roger Connors and Tom Smith are the four-time New York Times bestselling authors of an extensive body of knowledge on workplace accountability and are considered experts on the subject. Their company, Partners In Leadership, is a provider of accountability training and culture change services and has enabled thousands of companies and millions of people to achieve dramatic results. Learn more a twww.partnersinleadership.com.

Partners In Leadership, Accountability Training, Cultural Beliefs, and Culture of Accountability are all registered trademarks of Partners In Leadership, Inc. All other registered trademarks and trademarks used herein are the property of their respective owners.